Modernized tensile testing machines and new testing modules for precise material analysis

The FILK Freiberg Institute has comprehensively modernized its universal tensile testing machine, laying the foundation for even more precise and versatile mechanical testing. These innovations not only increase accuracy and reliability but also significantly expand the range of applications.

Condition monitoring and new measurement technology

The modernized systems are now equipped with a condition monitoring function that enables live monitoring of the machine's condition. This makes the testing process transparent, reproducible, and optimallydocumented. A new video extensometer also enables non-contact, high-resolution strain measurements – especially for sensitive or complex sample geometries.

Advanced testing options

With a new 3-point bending device, tests can be performed according to ISO 178 (bend testing of plastics) and ISO 14125 (bend testing of fiber-reinforced plastics). This makes FILK even better positioned for the mechanical characterization of modern materials.

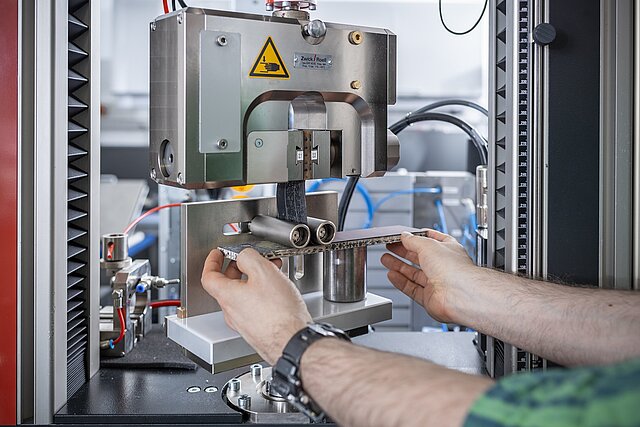

Roller peeling device for demanding composite tests

In addition, the laboratory now has a new roller peeling device that enables separation and peel tests on adhesive and layered composites – from flexible coatings to complex component assemblies. The tests are conducted according to current international standards and OEM specifications, including:

VW PV 2034 | DIN EN 1464 | ISO 29862 | DIN ISO 457 | DIN EN 1372 | ASTM D3330/D3330M | ASTM D6862.

State-of-the-art precision and process reliability

With this technical upgrade, FILK offers expanded capabilities in the mechanical testing of materials and composite systems – for the highest precision, comprehensive monitoring, and reliable results.