Head of Department

"The development of functional layer systems is extremely diverse and the required properties are multifarious. It is this broad spectrum that I particularly appreciate in my work. I am constantly excited to develop innovative research work, which contributes solutions to the industrial problems. What motivates me the most is to see a former idea finally resulting in a concrete application which is implemented by companies and utilised by end-users."

Profound Knowledge and Experience

To develop multifaceted functional polymer materials industrially established and continuous application processes like spread coating, gravure printing, extrusion or calendaring is used. New manufacturing concepts like alternative fabrication, drying and venting process complete the above continuous processes. In particular, Additive manufacturing process like printing of 2D and 3D objects or drying process by means of radio waves are promising choice. These processes are especially focussed for the establishment and advancement of flexible and elastic materials.

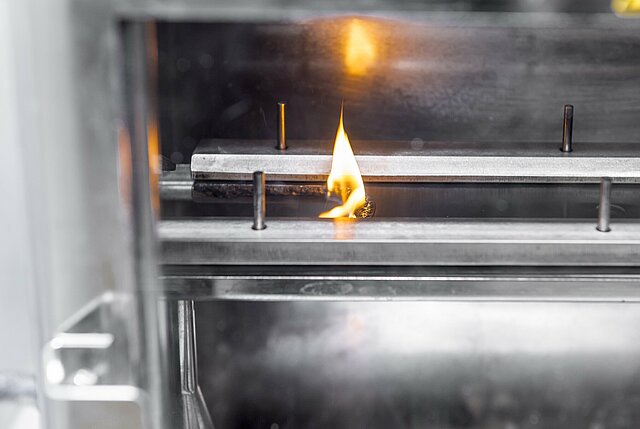

Furthermore, in developing materials with tailor-made properties, it is critical to formulate individual recipes. It is not only the chemical composition that matters for the preparation of application related polymer formulation but also their mixing to yield ready-to-use compound. Currently, materials for the field of smart textiles, flame retardant composites, polymer membranes or classical textile reinforced composites (synthetic leather, floor covering, tarpaulin) are developed. The polymer systems used for the above mentioned fields are polyurethane, polyvinyl chloride, silicone, polyolefins, polylactide or polybutylene succinate.

Our Services

In the field of functional layer systems we offer the following services:

Planning and execution of coating tests at our numerous plants

Preparation and manufacture of coating compounds of different types

Functional demonstration for functionalised composites