Head of Department

„ In our fast moving time new and high demands are consistently made on technical surfaces. Characterisation, functionalisation and further development of these surfaces is the exciting task of the scientists at my department. The aim is to create more durable and resistant surfaces and to give them customised mechanical, physical and chemical properties. What is fascinating and at the same time challenging in my work is the functionality of the surfaces in most different scopes of application, from medical products and food packaging via electronics through to motorcars, which consistently require new creative research approaches."

SURFACE PHENOMENA CLARIFIED

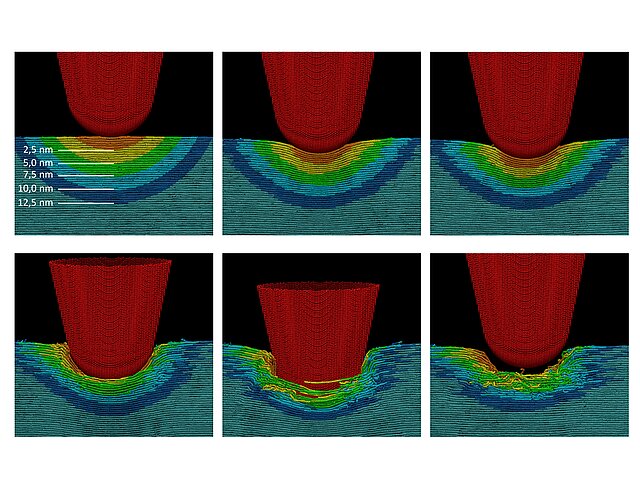

Surfaces are not a new field of research at the institute. This field of research derives from material expertise for most different flexible polymer materials and composites the surfaces of which play an important role during the manufacturing process, but above all with regard to usage. What first of all started with plasma coatings in the nanometre range, for instance to activate surfaces for improved adhesion or printability, has become a comprehensive field of research around the topic "surfaces" today. Meanwhile surface phenomena such as the quality perceived, the equipment of surfaces for creating most different functions, or the prediction of friction and wear properties of materials are researched at the corresponding research department.

Our Services

Our surfaces department offers the following products and services:

Surface modifications

Material characterisations

Tests with regard to the friction and squeak behaviour

Tests concerning the perceived quality

Haptic-standard-leather (as arule A4-pieces)

Performance of studies on subjective perception

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/4/c/csm__DSC2960medium_f53859956f.jpg)

![[Translate to English:] [Translate to English:]](/fileadmin/_processed_/7/f/csm_car-1709512_1920_646979673c.jpg)