1 General material properties, basic parameters

The general material properties describe basic parameters of materials. Being essential for the identification and categorisation of materials, in addition, the basic parameters directly and indirectly influence other specific material properties.

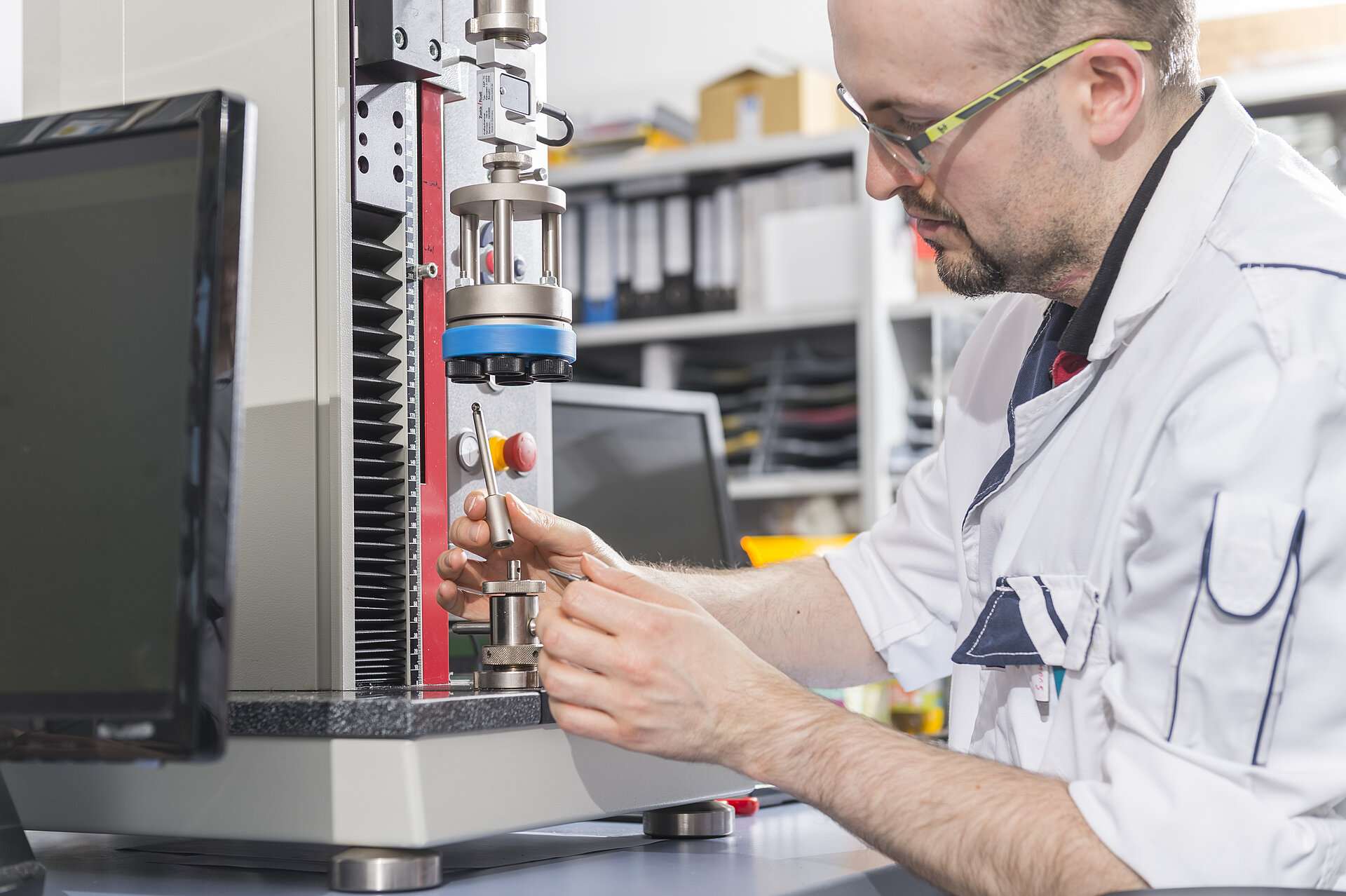

2 Strength properties and deformation behavior

In our accredited testing laboratory, we provide robust physical testing focused on strength properties and deformation behaviour—specifically for FILK-typical materials such as coated textiles, leather, artificial leather, multilayer composites, films and textiles. These materials are commonly used in automotive interiors, the furniture industry, and the footwear and fashion sectors.

Using application-oriented test setups, we determine relevant mechanical parameters and assess deformation behaviour under defined loads. Our results support you reliably in material selection, product development, quality assurance, and the validation of specifications.

In continuous or changing exposures to weathering and environmental conditions (e. g. artificial daylight or sunlight, temperature, humidity, climate), permanent mechanical loads or influences of further media on materials accelerated material ageing and material fatigue processes are induced. An extensive range of methods is available for determining the changes in physical material properties compared to the initial state, based on different ageing scenarios, storage and exposure conditions. The analyses provide important information on the specific application potentials, limits and durability of materials.

Abrasion and wear designate to changes induced by mechanical-tribological stress on materials’ surfaces. Depending on product and application requirements, the abrasion and wear properties of the friction partners are determined in relative motions. In linear (e.g. Crockmeter, Linear Abrasion Tester, Abrex®, VESLIC tester, etc.) as well as rotational (e.g. Taber®, Martindale, Schopper, etc.) load scenarios with application to dry, wet as well as media treated conditions, a variety of different methods are available for testing the abrasion and wear resistance properties.

5 Compatibility and resistance

The compatibility and resistance of materials to chemicals, preparations of media, simulants and microorganisms as well as dynamic mechanical loads are determined in various tests. According to the product and application requirements, the materials are brought into direct contact with water and aqueous solutions (e. g. artificial sweat, saliva and salt solutions), disinfectants, cleaning and care products (e. g. creams and cosmetics), organic solvents, oils and fats and operating media (e. g. fuels) in accelerated processes or are exposed in various artificially generated atmospheres (e. g. exposure to amines, nitrogen oxides (NOx)). The accompanying changes in the physical material properties compared to the initial state are determined. In addition, absorption, migration and penetration effects of various media (e. g. static and dynamic water absorption, water penetration, water resistance) as well as degradation, decomposition, delamination processes and other failure phenomena and damage characteristics (e. g. crack formation, whitening) are considered.

Fastness properties address the resistance of materials’ colorants to multiple external influences. Material surfaces such as lacquer and top coats as well as finishes are subjected to mechanical abrasion (e. g. rub fastness), irradiation (e. g. light fastness), various heat and climate storage (e. g. colour fastness, migration fastness) as well as storage in water and artificial solutions (e. g. colour fastness to perspiration, sea water, saliva, solvents) in processing and application relevant scenarios. Materials’ colour(contrast) changes as well as the colour(contrast) transfers by so-called bleeding of accompanying reference materials (e. g. rubbing and concomitand fabrics, foils) are determined with appropriate test standards (e. g. grey scale, blue scale). The fastness properties of materials represent essential material characteristics and provide important information on the usability, maintenance and long-term properties.

7 Soiling behavior and cleaning ability

The use and care properties of surface materials are mainly characterised by the soiling and cleaning behaviour. Depending on the specific interior applications, the respective soiling (e. g. solid and liquid soiling, food, various media) and cleaning steps (e. g. manual or instrumental) are carried out. In combination with various material aging processes according to defined specifications a wide range of test methods is applied. In addition to the determination of the specific material properties itself, these investigations also enable the quantification and assessment of e. g. novel "anti-soiling" and finishing systems for the material surfaces.

The processing and application-relevant surface properties of materials are determined on the basis of tactile, optical and destructive methods. The physical and topographical parameters to be determined, for example, hardness, scuff and mar resistance, degree of gloss, surface reflection, conductivity, surface tension/resistance, roughness and grain depth can be used to identify property-function relationships, providing important information for material development, process and quality control as well as for the identification of functional failures and certain damage patterns (e. g. delamination of layers) of materials.

9 Burning behavior and flammability

We perform tests on the burning behavior and flammability of materials according to numerous national and international standards and specifications.

Our flame tests include both standardized and customer-specific procedures for evaluating the ignitability, flame spread, burning rate, and flame resistance of various materials.

A key focus is on material testing for automotive interior components (various OEMs).

As a designated Technical Service A, we also carry out testing and consulting in accordance with UN ECE-R 118, including type approval through Federal Motor Transport Authority (KBA).The analyses of tribological properties of materials, in particular, the behaviour related to friction and wear, are essential elements in the applicability and durability of materials and products. In addition to the determination of, for example, coefficients of friction under laboratory conditions, realistic tests under certain climatic conditions or defined material pre-aging arrangements of the samples are of constant interest. Within these tribological tests, the stick-slip behaviour of material combinations is of special interest. Therein, the probability of various squeaking and creaking noises, caused by unfavourable material combinations, are determined.

11 Special testing and other methods

Within the scope of standardised as well as scientific-technologically adapted investigations, information and support for product development, production processes as well as product qualities can be derived. Based on the extensive possibilities of qualitative and quantitative material investigations, customer-related special tests and analytical procedures, specific damage and failure analyses, individual determination of usability, comparative material studies as well as investigations on marketability according to legal regulations can be achieved. In addition, these investigations can be applied within the scope of lawsuits and other disputes. I

Physical Testing

Contact

FILK Freiberg Institute gGmbH

Meißner Ring 1-5

09599 Freiberg

GERMANY

Fon: +49-(0)3731-366-0

Fax: +49-(0)3731-366-130

E-Mail: mailbox@filkfreiberg.de